Winery by-products as a source of essential compounds

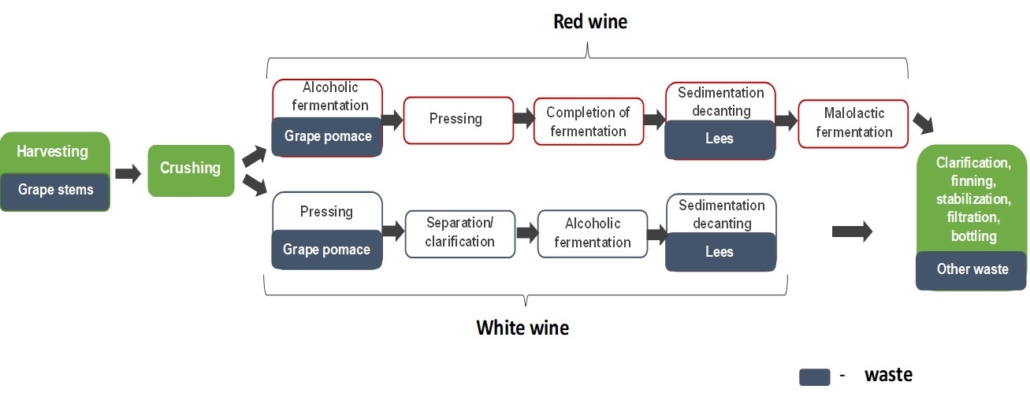

The consumption of wine has a great economic and cultural significance. According to The Food and Agriculture Organization statistics from 2016, the grape is the most widely cultivated fruit crop [1]. The biggest grape producers in 2018 were: China (11.7 million tons), Italy (8.6 million tons), the USA (6.9 million tons), Spain (6.9 million tons), and France (6.2 million tons) [2]. Among the others, grape crops are used for fresh fruit, dried fruit and juice production. However, the majority of production is focused on wine [3]. In 2019, the world wine production reached 292 million hectoliters from 77.8 million tons of grape crops. It is assumed that 30% of the total amount of vinified grapes are by-products during the wine production, including pomace – skin and seed as well as rachis and lees, as shown in Figure 1 [4].

In 2018 alone, vitiviniculture generated around 23 million tons of waste. Moreover, most of them were discarded without any treatment, causing an environmental and economic load. Biowaste generated during the winemaking process has one significant feature making them difficult to dispose of. They are rich in phenolic compounds, which decrease the pH and increase resistance to biological degradation [5].

Should they be considered waste?

Growing people’s interest in sustainability and circular economy is a driving force for the wine industry to look for innovation and an alternative way of winery biowaste utilisation. Winery by-products, especially grape pomace, present a rich source of essential compounds such as antioxidants, dietary fibres, polyphenols, flavonoids, essential minerals, showing health-promoting properties. It is documented that these bioactive compounds possess antibacterial, antitumor, anti-inflammatory, antioxidant effects preventing chronic diseases. Thus, they are highly interested in the food, cosmetics, and pharmaceutical industry [6]. More and more literature evidence shows an increasing number of possible reusing and recycling of winery biowaste. The extract of grape pomace can be used in various industries like:

- the food industry, where it can be added to prevent food products against oxidation and lipid peroxidation, to limit colour deterioration and prevent against the antimicrobial activity, thus food spoilage;

- the cosmetic and pharmaceutical industry, because of significant polyphenols content it could be a new, cost-effective source in the cosmetic sector due to their anti-ageing properties or dietary supplement rich in antioxidants;

- agroindustry as soil conditioner once the grape pomace is composted or it can be reused in animal feeding [5].

Instead of being disposed of away, winery by-products can be used as a fuel (biomass) to generate methane gas, which can then generate electricity [5]. Moreover, grape stalks can be used in wastewater treatment to remove heavy metals, including Cd, Cu, Cr, Ni, Hg, Pb [7].

The discussed number of wine pomace applications demonstrates the significant potential of winery by-product valorisation in various industries. The results of the research are very promising; however, still, there is a long way to go until all of these residues have proven recovery pathways. This is a huge challenge for the future, to make the wine production process more sustainable, to change the wine waste chain in order to recover as much as possible and turn it into valuable products.

“Who will be the first to benefit from exploring the opportunities?”

Written by Magdalena Fabjanowicz, Gdańsk University of Technology

References:

1. FAO-OIV FOCUS 2016 Statistical Report on Table and Dried Grapes. Available Online: (Accessed 16.03.2022); s.n.], 2016;

2. OIV, 2020 Statistical Report on World Vitiviniculture. Available Online: (Accessed 8.03.2022);

3. Bouquet, A.; Torregrosa, L.; Iocco, P.; Thomas, M.R. Grapevine (Vitis Vinifera L.). In Agrobacterium Protocols Volume 2; Humana Press: Totowa, NJ, 2006; pp. 273–285.

4. Melo, P.S.; Massarioli, A.P.; Denny, C.; dos Santos, L.F.; Franchin, M.; Pereira, G.E.; Vieira, T.M.F. de S.; Rosalen, P.L.; Alencar, S.M. de Winery By-Products: Extraction Optimisation, Phenolic Composition and Cytotoxic Evaluation to Act as a New Source of Scavenging of Reactive Oxygen Species. Food Chemistry 2015, 181, 160–169, doi:10.1016/j.foodchem.2015.02.087.

5. Kalli, E.; Lappa, I.; Bouchagier, P.; Tarantilis, P.A.; Skotti, E. Novel Application and Industrial Exploitation of Winery By-Products. Bioresources and Bioprocessing 2018, 5, 46, doi:10.1186/s40643-018-0232-6.

6. Gerardi, C.; D’amico, L.; Migoni, D.; Santino, A.; Salomone, A.; Carluccio, M.A.; Giovinazzo, G. Strategies for Reuse of Skins Separated From Grape Pomace as Ingredient of Functional Beverages. Frontiers in Bioengineering and Biotechnology 2020, 8, doi:10.3389/fbioe.2020.00645.

7. Tripathi, A.; Rawat Ranjan, M. Heavy Metal Removal from Wastewater Using Low Cost Adsorbents. Journal of Bioremediation & Biodegradation 2015, 06, doi:10.4172/2155-6199.1000315.